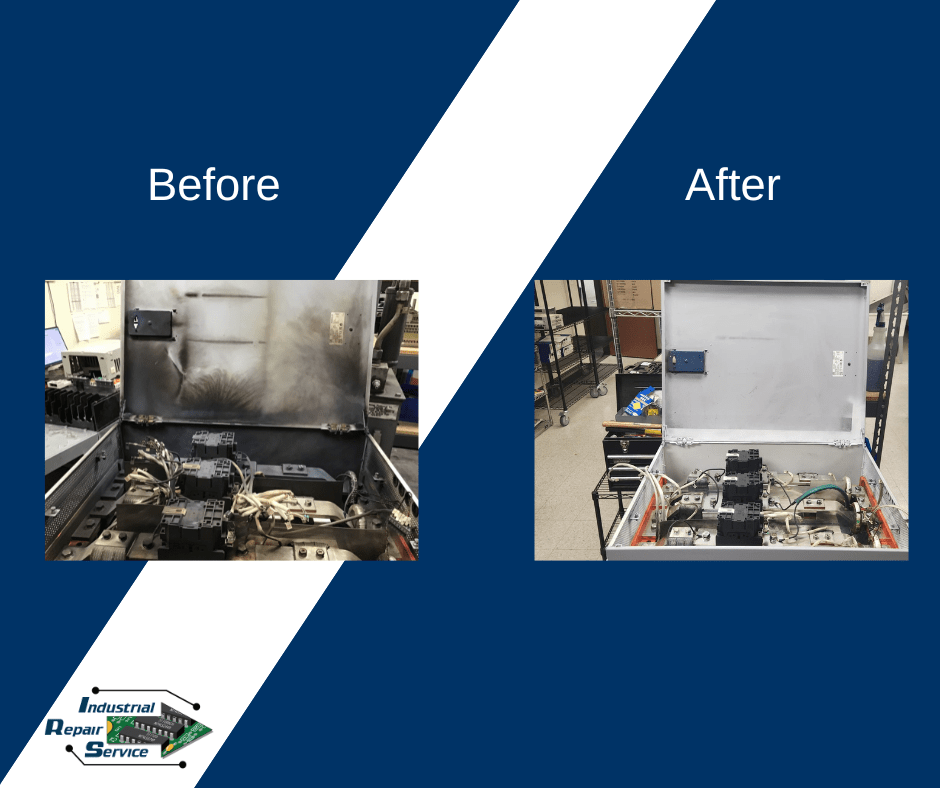

This month, we’re excited to share a transformation from our Dallas-Fort Worth, Texas, location!

Recently, we received a WEG Soft Starter that was in bad shape. We didn’t have any specific details about the initial equipment failure and its symptoms. However, our DFW shop was able to diagnose and resolve all its issues. After the initial inspection, our technicians notified the parts team of all components required for the repair, and after retrieving the necessary items, they began work.

Here are the repairs our techs conducted for the static starter. Our team replaced…

- The connector(s)

- The processor

- The resistor(s)

- The transformer

- The trace damage

- The capacitor(s)

- The IC(s)

- The SCR(s)

Afterward, our test procedures included a component/system check and concluded with a power-up and voltage run. For quality control, the unit had a final cleaning, was prepped for shipping, and was ready to be returned to the customer.

The “before” and “after” pictures display our team’s ability to restore equipment to optimal condition, even without specific failure details. All of our locations at Industrial Repair Service prioritize top-notch service to minimize downtime, reduce costs, and get your equipment back up and running. We’re proud of our Dallas-Fort Worth staff and their commitment to providing unparalleled service and caring for our clients’ valuable pieces with diligence. Stay tuned for more transformations from our other locations. If you need a repair, call us today!

Leave a comment