This month’s transformation story comes straight from our sunny Phoenix, Arizona, location with a blown-up AC drive.

Sent in from one of our customers, they explained that the initial problem stemmed from a water drip leaking into the unit. When they tried to power on the drive, it wouldn’t start. This valuable broken-down component was causing downtime in their operations, so they decided to send it to us, the experts!

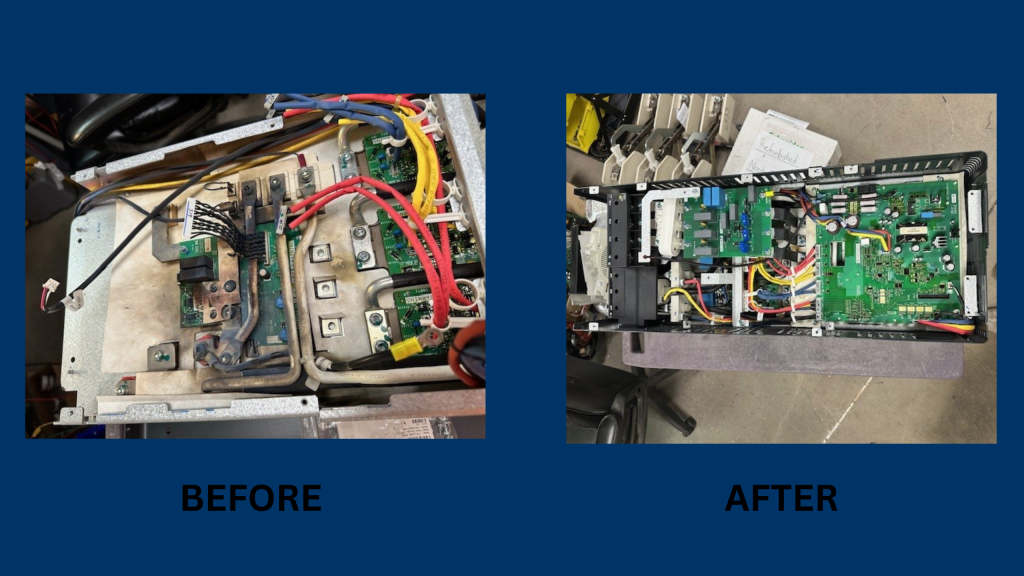

First, our tech used his meter to measure the DC+ and DC- inputs and outputs, and quickly saw that there was no input (it was shorted). Upon disassembling the unit, the inside showed a clear indication that there was a significant problem. After spending around one and a half hours troubleshooting and digging into all the unit’s issues, he repaired the following (as indicated on his report that gets sent to every customer after completion of their item):

- Repaired cold solder joint

- Replaced output transistors

- Replaced aged capacitors

- Replaced the DC filter board

- Replaced blown input IGBT module

To ensure the drive was in working condition, our technician ran the motors and recorded a video of the drive successfully operating for our customer. It was cleaned and shipped back in prime condition, ready to be used to the utmost of its capabilities!

The “before” and “after” photos showcase our Phoenix team’s dedication to delivering exceptional service and getting our customers back up and running. Industrial Repair Service aims to reduce your costs and improve the efficiency of your operations while providing unparalleled service and caring for our clients’ valuable equipment with diligence.

Call us today and stay tuned for more transformations from our other locations nationwide!

Leave a comment